Die casting is a metal smelting process, in which molten alloy under the action of high pressure is forced to fill the cavity of a steel mold at high speed. The alloy solidifies under pressure to form the casting method. This process is somewhat similar to “plastic injection molding”. The main characteristics that distinguish it from other casting methods are high pressure and high speed.

1, The features of aluminum die-casting.

Durability

Due to the stability of aluminum owing to oxidation resistance, aluminum alloy castings will not rust i.e they are corrosion resistant. Surface electrostatic powder coating and fluorocarbon coating ensure that the casting remains vital for a long time. Feiyu-manufactured products can be maintained for a long time without fading.

Plasticity

Due to the ductility of aluminum, it is easy to design a variety of shapes with alloy casting. The casting is tough and can be repeatedly recycled. The application range is more extensive.

Safety

After various strict tests, it has been discovered that the aluminum alloy casting method makes the manufactured products lighter in weight. This reduces the burden of handling heavy construction work and minimizes accident occurrences.

Creativity

It can create more attractive designs for products according to the different demands of the market.

Lightweight

Aluminum alloy die-casting is light in weight, convenient to use, and easy to carry.

2, Advantages of aluminum die-casting.

High product quality

There is a high dimensional accuracy of die casting, high surface finish, high strength, and hardness as well. Strength is generally 25-30% higher than sand casting, but the elongation is reduced by about 70%. Also, aluminum die-casting alloys possess high dimensional stability and good interchangeability which is good for making complex parts.

High production efficiency

The Horizontal Cold Air, die-casting aluminum machines run an average of eight hours per day and can die-cast aluminum 600- 700 times. On the other hand, the small Hot Chamber die-casting aluminum machines run an average of eight hours per day and can die-cast aluminum 3000- 7000 times.

Excellent economic effect

Owing to the accurate aluminum die-casting size, the pros of the table pan are clean. Generally, no longer mechanical processing and direct use, or very small processing, both improve the utilization rate of metal and reduce a large number of processing equipment and time.

3, Disadvantages of aluminum die-casting alloys

- Due to the high speed of the liquid metal filling the steel mold cavity, the flow state is not stable, and this is why castings are easy to have pores, and can not be heat treated.

- The inner concave complex die-casting molding difficulties reduce production efficiency.

- Aluminum die-casting mold has a short life. It can only take about 80,000 injection times.

- Not suitable for small batch production. The reason is the high cost of the aluminum die-casting alloys manufacturing

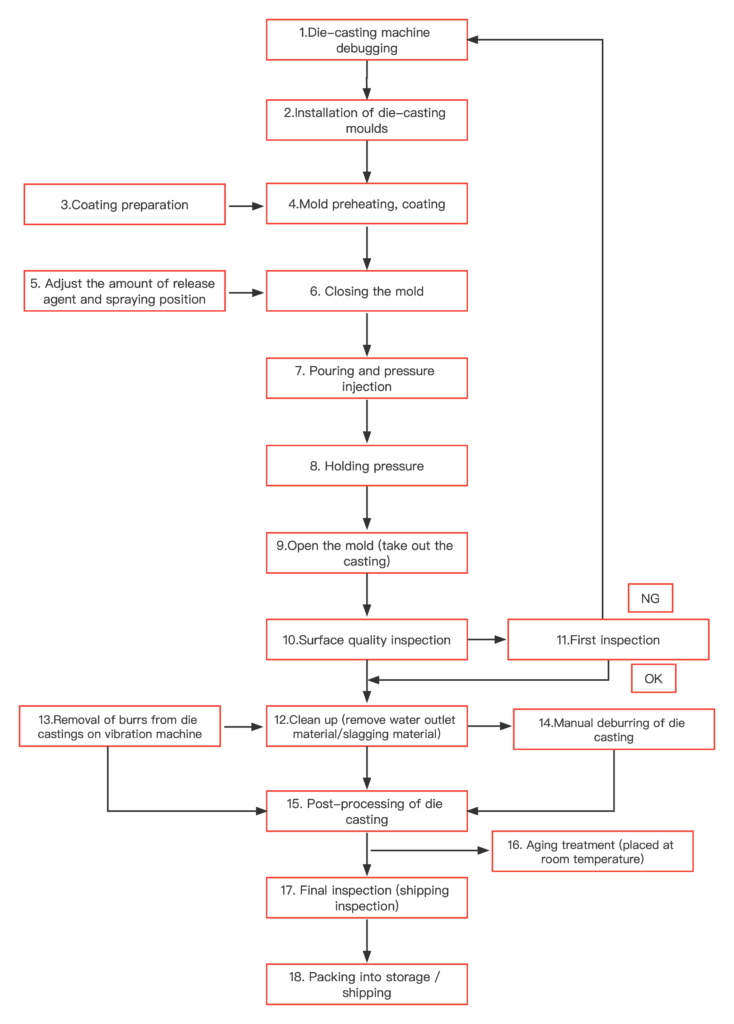

4, Aluminum alloy die-casting production process flow chart.

Quick Links:

🔗Detailed Tour of FEIYU Factory – Environment